Electroplating Processes

Nikasil Coating

We offer a diverse range of advanced electroplating and metal finishing services. Serving customers across Melbourne & Australia.

Electrosil offer our unique version of Nikasil which we can coat not only inside bores, but also on other wearing parts such as pump impellors, brake rotors, rotary seals etc.

Anything that suffers from sliding wear is a potential candidate for our process, and we are able to coat on to many different aluminium alloys/castings as well as most steels (cast, mild, high carbon etc). If we are unsure about coating adhesion on a particular substrate, we may request a sample piece to coat and machine to ensure adhesion and durability.

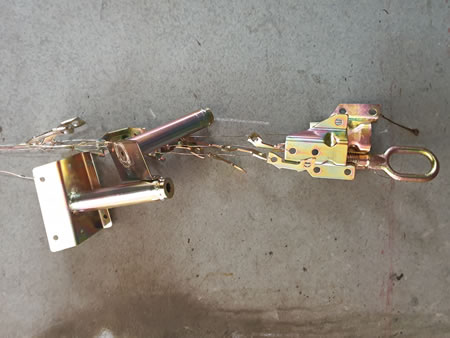

Zinc Plating

Long before we were a Nikasil coating and cylinder reconditioning business, we were a diverse Electroplating business.

Unfortunately we’ve had to close down many of our plating lines, however we’ve kept a small zinc electroplating tank in use.

Zinc plating offers excellent corrosion resistant properties, and is fantastic for reclaiming old rusty nuts, bolts, screws, springs, hinges, side stands etc.

We don’t use barrel plating like a lot of larger electroplating shops use in their lines, instead we wire our jobs up by hand with the utmost care so ensure a clean, even deposit.

Our zinc coating can be chromate converted with either a blue (silver), yellow or olive drab finish.